Driving safety, especially for a taxi or any passenger vehicle, depends heavily on headlights, which provide essential illumination of the road ahead and guarantee vision in bad weather. For any taxi service, this operation is mostly dependent on a complex network of wiring tying the power supply to the headlights. On the road, wiring problems could cause dim lights, flickering beams, or complete failure, posing serious hazards for reliable taxis navigating busy streets. Effective diagnosis and repair of these problems depend on a knowledge of headlamp wire operation, something every York taxi operator should understand. From the battery to the switch and finally the bulbs themselves, every link has to be intact and working, especially in a taxi in York, where frequent night journeys mean headlights must always be at peak performance.

Identifying Common Wiring Problems

Determining the precise electrical problem at hand is essential before beginning any repairs. Frayed wires, blown fuses, and loose or corroded connections are common issues. The first step is to thoroughly examine the wiring harness, looking for any obvious wear or damage. Using a multimeter to test the circuit might also show voltage dips or broken connections. It’s crucial to inspect the switch as well because a broken switch can resemble wiring issues. A repair strategy can be developed after the problem’s origin has been determined. For reliable diagnostics and repairs, Auto Repair in Aurora, Co, offers expert services to address your vehicle’s electrical issues efficiently.

Repairing Loose Connections and Corrosion

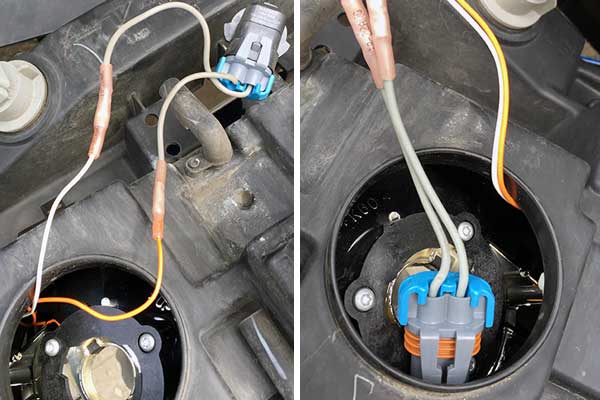

Loose or corroded connections are one of the most common causes of headlight problems. Frequently, these can be fixed with very few tools. To be safe, first turn off the car and unplug the battery. Next, find and carefully examine the wire connections that lead to the headlights. Use sandpaper or a wire brush to clean it if you find any corrosion. Verify that every connector is tight and, if required, twist tightly. It can be necessary to replace a connector completely if it is excessively damaged. After the repairs are completed, check to see if the problem has been fixed by reconnecting the battery and testing the headlights.

Dealing with Frayed Wires

Your headlights’ performance can be greatly impacted by frayed or damaged cables. Heat shrink tubing or electrical tape might be able to fix it if the damage is modest. The best course of action for more serious damage is frequently to cut out the damaged segment and splice in a new length of wire. Use solder or wire connectors to firmly link the new wire after splicing, making sure to remove enough wire to enable a strong connection. Always use heat shrink or tape to insulate the connection to prevent abrasion and moisture damage.

Conclusion

Preventing headlamp wiring issues requires regular maintenance. Regularly inspect headlight wiring and connectors for wear and damage, especially in damp or rusty places. Clearing dirt and cleaning around headlights can also prevent corrosion. High-quality wiring and watertight connectors extend headlight system life. Car owners may ensure reliable lighting and safer driving by adopting proactive actions.

Comments